Guide to Warehouse LED Lighting

The use of LED lighting is on the rise in warehouses with companies reaping the benefits of huge energy savings and reduced maintenance costs. Warehouses and industrial buildings can present harsh environments – lighting may be required to operate in extremes of temperature and humidity, may be exposed to atmospheres that are corrosive, explosive or dirty, and may need to be capable of withstanding water jets and vibration.

Fluorescent banks of tubes are renowned for their frequent flicker, buzz and not to mention, huge energy drain. Poorly lit warehouses waste energy and can cause health/safety hazards. LED lighting for warehouses provides brighter, whiter and more reliable lighting replacements that use a fraction of the energy to run and maintain. Your investment into industrial LED lighting provides return on investment from as little as 3 months. It also provides better staff safety, and improve the overall warehouse working environment.

When planning or upgrading the lighting in your warehouse there are a range of factors to consider:

- – To provide general lighting of the whole area appropriate for the average level of task difficulty

eg. localised lighting where work is concentrated, or where obstruction reduces the visibility of

the task, or where there is an obvious hazard - – Be able to facilitate quick and accurate work by workers within the warehouse

- – Natural light availability e.g. ceiling skylights and doors

- – Pre-existing conditions e.g. dirt, dust, potential temperature extremes

- – Meet safety standards and create a comfortable visual environment

Other factors which will be taken into consideration when producing lighting layouts and designs include the size of warehouse, height of ceilings, high and low traffic areas, the width between aisles, open spaces and difficult-to-access areas, shelving heights and existing wiring, sensors and emergency lighting systems.

What Type of Light Source Should Be Used?

Traditional lighting like fluorescent, HID, metal halide and SON are old, antiquated and energy draining. Nowadays, the ultimate energy efficient choice for lighting your warehouse is with LED lighting fixtures. They use dramatically less energy than any other light source while emitting more efficient lumen outputs. LED warehouse fittings can either be purchased as complete fixtures for new buildings or retrofittable ones which replace existing lighting. They can last up to 100,000 life hours which is 5-10 times the lifespan of traditional lighting. You won’t have to drag out the ladder or lift to replace an LED bulb nearly as often because they aren’t reliant on ballasts and gear (which requires replacement and maintenance) and they don’t suffer from constant on/off cycle switching the way traditional lighting does.

What LED fittings are suitable for Warehouses?

- Round LED High Bays. Designed to replace HID lighting including SON and metal halide high bay fixtures 400-600W and is suitable for installing in warehouses from 6m and above. With multiple beam angles which can produce focused or general lighting, the typically round fixture (also known as a UFO High Bay) is easy to suspend or surface-mount onto any ceiling type. The Ovo LED High Bay (IP66) with SMART controls provides even more functionality, with highly efficient, bright light output from 13,700 to 22,500 lumens. With integrated SMART sensor control, it senses occupancy and daylight, controlled by a simple lighting app.

The Ovo LED High Bay dims down to an ambient level when no one is around, or there is enough daylight present. It automatically dims back up when it senses movement or lack of natural light. By optimising usage, it adds a further 15-20% energy saving potential. Busy aisles and warehouse zones lighting remain switched on as needed, but areas where the footfall is not continuous or irregular are automatically controlled. You can set a target lux level which is maintained by all the light fittings that are grouped together, or control each fitting individually. The Ovo High Bay is totally glass-free making it ideal for food and drink environments, ensuring no glass contamination. Learn more about Ovo here - Linear LED High Bays. The GX2 Linear LED High Bay (IP65) is suitable for warehouses and industrial buildings with ceiling heights from 4m to 12m. Replacing traditional metal halide and SON high bay fixtures up to 600W and reaching up to 130 at up to 24,00 lumens, the GX2 features an opal PC lens for crisp, even illumination for racking and aisle applications, warehouse bays, aisles, shelf faces and general lighting. Incorporating 5 Way Protection against the elements, the GX2 is protected from water ingress, dust, heat, ice and corrosion. Dimmable & Emergency LED options available. The GX2 Linear LED fitting is made of aluminium and polycarbonate i.e. no glass, so highly suitable for food, drink & pharmaceutical environments ensuring no contamination. Learn more about the GX2 here.

- Linear LED battens. These replace standard fluorescent tubes and fixtures, with relevant IP ratings, so that they are suitable for installing both internally and externally in warehouse environments. The Goodlight G5 LED Batten (IP65) is a sleek, modern LED batten with IP65 protection suitable for ceilings, walls, interior or exterior. The G5 features a 120° beam angle for optimal light spread and looks smart and stylish. Watch the G5 LED batten video here.

With a rugged, waterproof body (IP65) and an impact protection rating of IK08, the Eco LED Batten has been designed for tough environments including warehouses, cold storage, refrigeration, food and drink production, factories and industrial environments. This fitting, along with all of our LED Battens, is glass-free and features a shatterproof PC lens. Find out more about the LED Eco Batten here. Delivering over 130Lm/W, the LED Batten Pack provides ultra-bright light output and up to 65% energy savings. The Batten Pack has been designed with multi-colour white LEDs that produces switchable colour temperatures, ideal for lighting industrial spaces. Find out more about the LED Eco Batten here . - LED Low Bays & Floodlights. Low Bays are an LED option for warehouses which currently have traditional low bay or floodlight fixtures. This heavy-duty LED luminaire can also be mounted externally with IP66 protection, and can be operated as bay or floodlighting to suit the environment. The GX1 LED Low Bay provides lumen outputs of 16,800 to 47,800 of high output and is suitable for installing into warehouses from 4m. Find out more about the Gx1 LED Low Bay here.

How Bright Should my LED fittings Be?

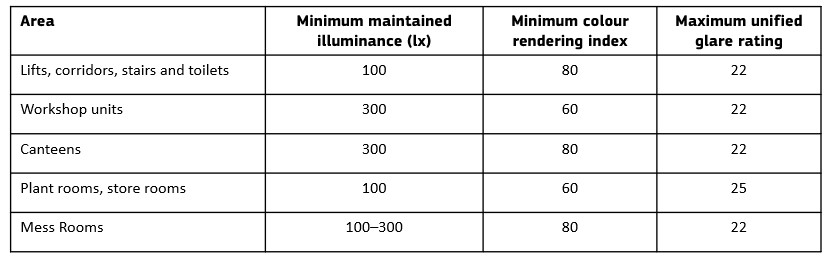

LED light fittings vary in wattage and light output – as a guide, the higher the wattage the brighter the fitting will be. However do look out for how many lumens per watt the fitting can provide, as this relates more to the ‘energy efficiency.’ E.g. a fitting quoted as 100Lm/W will be providing 100 lumens per watt of energy, so a LED light that is delivering 150 lumens per watt would be brighter – whilst using less energy. According to the latest guidance from CIBSE – here are the recommendations for lighting levels, colour rendition and glare ratings within various parts of the warehouse.

The interiors of Warehouses can help brighten things up too!

The colour of your ceiling, walls and floor can make a huge difference in illuminating areas. Light-coloured interiors have a higher reflectance than dark colours meaning they will amplify your light levels rather than muting them. If your warehouse has skylights, you can make the most of daylight streaming into your spaces, and use dimmable, controllable lighting can maximise energy savings. When replacing old lighting, painting walls and floors in light colours can help brighten areas where visibility is poor due to dirty surfaces or uneven due to objects in the way, like stock or equipment.

Which LED colour temperature should you choose?

Studies show that LED lighting helps to create a productive work environment. The choice of temperature can make a significant difference in overall eye comfort and visibility for warehouse staff and in the colour rendition (Ra) of products and equipment. The higher the temperature, the more level of ‘coolness’ in white light blending better with daylight. The correlated colour temperatures (CCT) of light sources commonly used in warehouse vary from 4,000K to 5,000K. Often 3,000K is known as ‘warm’ white. Cleaner, whiter light can aid concentration, reduce eye strain and increase productivity in the warehouse or production floor, whilst warm light improves the ambience in staff communal areas.

The choice of colour temperatures depends on what tasks are performed , e.g. if it involved detailed inspection work where you need to pick or spot variations in a blue colour range, then you would additionally need a high CRI value above 90 combined with a cool colour temperature which would provide the maximum brightness.

Which Light Distribution Type Should Be Used?

Warehouses typically need one of two light distribution types, depending on the layout of the facility. Space with tall shelving units need long and narrow light output. This ensures none of the light is lost or blocked by the top of the shelves. If you have more of an open floorplan, a type V light distribution is more appropriate to emit light in a wide spread from all sides. Our lighting design team are on-hand to guide you through some of the more technical aspects, such as light distribution – we can provide a lighting design for your building to show you what would work best.

How Should the LED Lighting Fixtures Be Positioned?

The spacing of your light fixtures is critical. If they are positioned too close together, you’ll experience glare where the light from one fixture overlaps with the next. If they are positioned too far apart, you’ll get illumination “drop-off” or dark areas. Depending on the horizontal and vertical space of the warehouse you will have to set the right wattage of the light and number of fixtures. For maximum coverage with brighter lights, 150 watts high bay lights are adequate for 15 feet wide spaces. Switching to LED lighting fixtures quickly reduces the requirements of the overall maintenance and the number of fixtures needed. Ask about our lighting design service, which will calculate how many fixtures you need and at what spacing to deliver the required lighting performance.

The use of Motion Sensors and Occupancy Monitoring with LED lighting

Many warehouses are operated 24/7. Warehouse lights with control options like motion sensors to get maximum utility out of your lighting and reduce energy consumption. You can opt for standalone sensors (PIR or microwave) or lighting fixtures with integral sensors to provide automated control of lights according to need.

When it comes to lighting large spaces like warehouses, sensors are essential to reduce energy costs by turning the lights on and/or off, depending on whether or not someone is in the space. Simple sensors turn the lights on and off. SMART sensors do alot more – they turn lights on, off or dim them up and down which is far more useful in busy buildings. With the advent of IoT and SMART lighting, we can programme the lighting to do exactly what we want or need. This means we can set various lighting levels by task or usage within the same building and make our lighting far more suited to the activities taking place. Our SMART lighting controls platform Light Boss provides digital, networked, lighting control with a host of other features. Light Boss SMART IoT automates energy savings and optimises for daylight and occupancy by operating lighting when and where it is needed, monitors lighting & energy use remotely, provides fault diagnostics and auto self-tests connected Emergency lighting. With Light Boss, no engineers are needed to attend site to investigate lighting faults! Learn more about Light Boss, your Virtual Lighting Engineer here

Eager to start your warehouse lighting project? We can offer a complimentary lighting design and report to show how much you can save in costs and carbon.

Give our team a call on 01276 691 230 or [email protected]